With the completion of a state-off-the-art manufacturing facility, Lee Michaels is now pleased to offer additional services to create, recycle or reimagine favorite jewelry pieces. The end of 2022 brought the ability for Lee Michaels to help create a custom piece of jewelry, to offer extensive new repair options and the ability to give an heirloom piece of jewelry or gemstone a new life by recycling materials and creating something fresh. In order to make that happen, the Berg family worked closely with industry professionals and built on Lee Michaels over 45 years of experience in the fine jewelry business to design and build out a state-of-the-art manufacturing facility, to offer this range of services in house and at an incredible value to customers. Lee Michaels is also excited to add two bench jewelers, with a combined 60+ years in the custom jewelry business, to our team.

With roughly 26 years in the industry, Chris Davis has the technical prowess to design and manufacture jewelry as his skillset combines a knowledge for modern technology paired with a creative mind to make it happen. Davis began his career in the polishing department for a local jeweler. While working, he attended night school for Jewelry Stone Setting and earned a Master’s Stone Setting certificate. In 2009, Davis was approached and agreed to learn CAD design and 3D printing. He unhesitatingly agreed to the challenge, and with research from books and a very limited availability of online resources of the time, he has successfully translated that knowledge in to a thriving career, trailblazing custom jewelry design and execution.

Troy Racca has used his artisanship to create numerous custom jewelry pieces for many high-profile figures, including three Louisiana governors, an Attorney General, and several players and coaches for the New Orleans Saints. Despite his popularity among local celebrities, Racca most enjoys using his skillset to help partners create something meaningful and personal with which to propose marriage. Racca has almost 34 years in the jewelry design business and has been able to learn trade skills thru professional experience on the job. The creativity, focus and craftsmanship that Racca exudes in his work translates to beautiful, one-of-a-kind jewelry. Continuously learning and growing his craft, the path to custom jewelry design is never-ending and Racca says his experience from “SKH, the School of Hard Knocks,” keeps him focused on his ability to create something meaningful.

Andrea was gifted a ring from her grandmother. The ring featured three round diamonds stacked diamonds, prong set, centered on the front of a multi-split shank band. After discussing with her grandmother, Andrea decided she wanted to give a fresh look to this heirloom piece. She worked with the Lee Michaels manufacturing team to reimagine the ring in a more contemporary style, but just as meaningful in history. Chris and Troy advised Andrea to look online at pendant settings and find a style that speaks to her personal taste. With her preferences in mind, Troy asked Andrea a few personal questions regarding her family heritage, birth months of her children, and things that could inspire the design. During their discussion, Troy started drawing out a filigree pendant design that would surround her round diamond. Chris was excited and eager to lend his skills to the technical renderings of this design. As Troy was sketching he was explaining to Chris details such as what would be an open space or a closed space, what they would do on the back to stabilize the piece, and how the design should be a piece with depth and not something flat. Chris masterfully translated the sketch and details from Troy to a CAD rendering, Andrea was in love with the design and then the team got started.

Troy conceived an idea for a scroll pattern pendant showcasing the largest of her three stones in a center bezel. These “napkin sketches” are a great starting point for something unique and enables the client to partake in their own custom jewelry design. We can also interpret images and videos from the internet as inspiration.

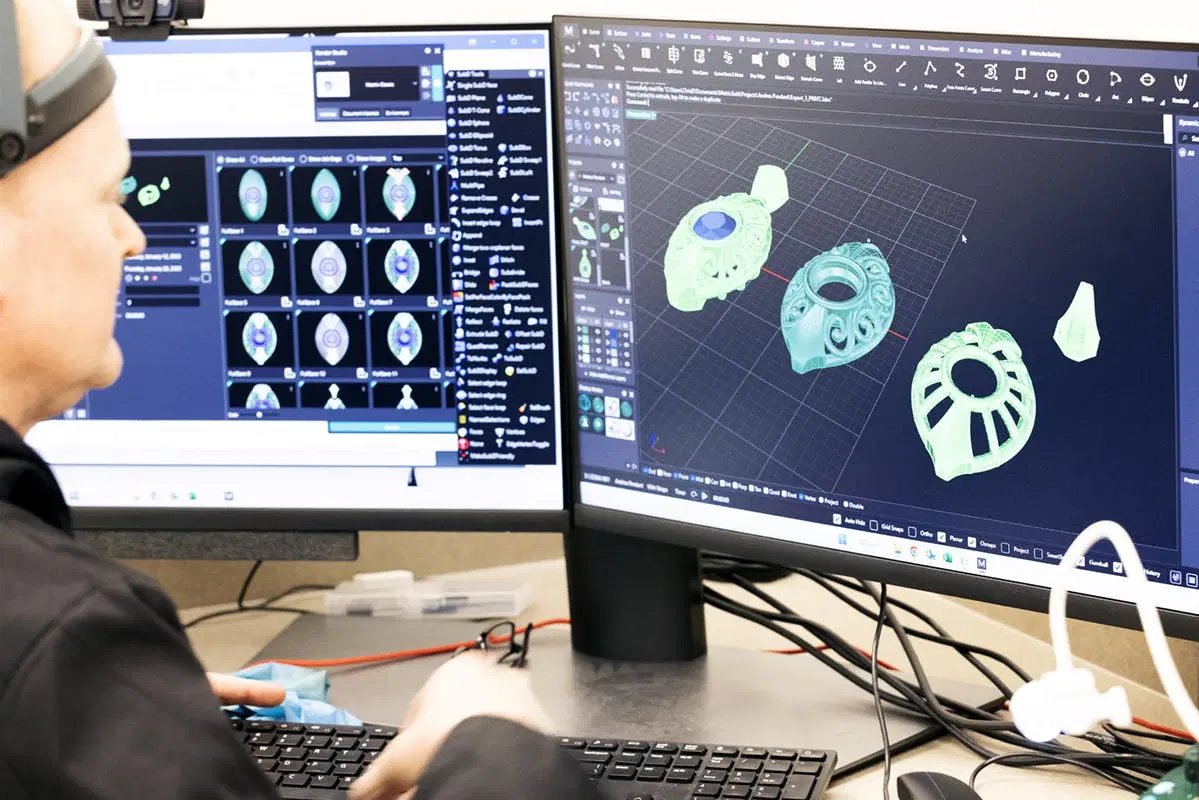

The hand drawn illustration is composed into a 3D CAD model. This will be rendered into lifelike images and sent to the client for approval. Unlimited iterations and modifications can easily be made to meet the client’s expectations.

A prototype of the design is 3D printed with perfect dimensional accuracy and prepared for casting. The flask will be filled with an investment slurry and allowed to solidify. It will then be placed into an oven where the 3D prints are burned out completely leaving a void for metal entry.

Troy has placed the casting metal into the crucible and is readying the machine. Once the casting metal has liquified completely Troy will introduce the molten metal to the investment flask filling the void left by the previously burned out 3D prints. We have the capacity to cast any karated metals from gold, platinum, and silver.

Chris is using a ‘thrum’ technique to polish hard to reach areas of the metal casting. Our goal is to create the highest quality custom jewelry with hand-crafted quality.

A coating of Rhodium plating is applied to the polished pendant to create an ultra-white mirror finish. From here it’s packaged and shipped…

The craftsmanship that both Davis and Racca bring to Lee Michaels is extraordinary. Only recently has CAD design for jewelry production been offered in colleges and universities, as an elective, and is still an extremely niche skillset. In the past, printing jewelry at such high resolutions was volatile and prone to failures which required lots of reverse engineering to prevent repeated mistakes. We are pleased to offer the services of Chris Davis, Troy Racca and all the jewelers of Lee Michaels Fine Jewelry stores to assist with the production, reimagining, refinishing and repairing of jewelry settings and stones. Inquire more at a Lee Michaels Fine Jewelry store near you.

You have questions, we have answers!